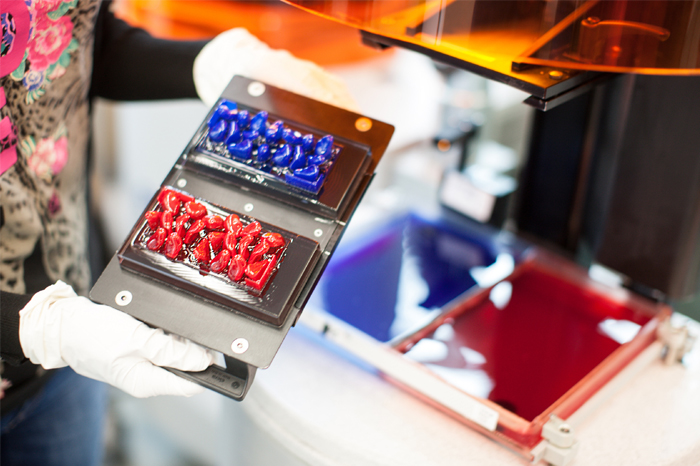

3D printing technology for making ear moulds

Ear Moulds:

Digital printing of custom-fit ear devices for the audiology, noise protection and customer audiology industries has never been so affordable.

Precision Materials:

This new technology moderates shell forces during printing to produce consistent, accurate prints for your treatment centre. Print small hearing aids, or large ear moulds, in just a few hours, to bring high-grade reasonable-cost printing to Audiology.

Digital Agility:

Flexibility is vital to running cost-effective production, especially in a business where volume orders can look at the sudden sign. Take control of your making infrastructure with preservative manufacturing which balances seamlessly with throughput needs.

The Perfect Custom Fit Knowledge:

Form 3B excels by offering precisions as low as 0.25 mm. Products prototypes and end-use parts with the ultra-fine exterior finish, ensuring your customer has the best audio seal and the calmest fit possible.

The Ultimate Audio 3D Printer:

Price. Precision. Simplicity. Form 3B is the result of years of study and development, relating hardware, software, and materials as a complete 3D printing network.

Reasonably priced Digital Performance:

From print preparation software to simple post-processing. A professional digital workflow has never been more reasonable.

Amazing Superficial, Every Time:

Perfect prints and reduced post-processing using Low Force Stereolithography (LFS) means your lab and health centre saves time and money.

The Digital Eco-System from Form labs:

Create your print job with Preform, post-process with Form Wash and Form Cure, and track development in Dashboard. Simplicity from start to finish.